IR Cut Filters

BAG IR Cut Filters

What are BAG filters?

BAG stands for "Blue Absorbing Glass." BAG filters are original products developed by TAMA Electronics.Our products feature an infrared absorption film formed over a conventional IR cut filter. This results in reduced shifting caused by incident angle dependence compared with conventional IR cut filters or BG (Blue Glass) filters.

We use optical glass as our glass substrates due to the material's high transmittance and strength. Its properties do not change even when reduced to the thickness of a film type substrate (0.1 mm), which allows it to help reduce the thickness and weight of modules and applications.

The benefits of BAG

With the BG method, the product is made by mixing the material that provides the absorption capability with the glass material itself. If the thickness of the glass is reduced...

(1) Infrared absorption capability suffers and

(2) The glass becomes frail

With the BAG method, the glass material itself is not touched, so the strength of the glass is not affected. Compared with the BG method, a product produced using the BAG method will offer greater strength at the same thickness. Infrared absorption capability is provided by the infrared absorption film formed on the surface, so performance does not rely on the thickness of the glass itself.

More and more absorption type IR cut filters are being used instead of conventional reflective type IR cut filters. Some examples of applications include laptop computer, 360 degree spherical camera, smartphones, wearable cameras, vehicle-mounted cameras, security cameras, and DSC/DSVC/DSLR products. Absorption type IR cut filters offer only minor shifting caused by incident angle dependence, making them perfect for shooting wide areas with a wide-angle lens at a close distance, or for designs featuring reduced module height required for smaller and lighter applications. These glass-type filters offer superior heat resistance over film-type products - meaning that heat generated from sensors will have no impact on image distortion or the like.

Product Estimates and Inquiries

Click here to request an estimate or sample, or to contact us.

Our products are also available in small lots, so feel free to contact us no matter what quantity you require.

Standard products and sample BAG IR cut filter

1. All of our BAG IR cut filters have the feature of low shift.

2. The thickness of each product is the thickness provided as standard.

3. All product and sample thicknesses can be made on request.

(Thickness is from 0.1mm to 1.1mm, please contact us for other thicknesses)

4. Even if the thickness changes, the optical characteristics do not change.

| Type | Serial No. | Model name | Transmission band / characteristics | Thickness |

|---|---|---|---|---|

| UV/IR Cut Filter | BAG-001 | GX0034B | 415nm-640nm | 0.21mm |

| BAG-002 | GX0044B | 415nm-650nm | 0.10mm | |

| BAG-003 | GX0083B | 400nm-650nm | 0.21mm | |

| BAG-004 | GX0086B | 415nm-640nm | 0.10mm | |

| APF-001 | GX0070B | 400nm-655nm | 0.30mm | |

| Dual bandpass filter (UV / IR cut, near infrared bandpass ) |

BAG-005 | GX0039B | 400nm-650nm-850nm (Standard specifications) |

0.21mm |

| BAG-006 | GX0097B | 400nm-650nm-850nm (Near infrared side low shift specification) |

0.21mm | |

| BAG-011 | GX0122B | 400nm-650nm-850nm (Near infrared side low shift specification) |

0.145mm | |

| APF-002 | GX0127B | 400nm-655nm-940nm (Standard specifications) | 0.50mm | |

| Bandpass filter | BAG-009 | SAMPLE | 850nm (Near infrared side low shift specification) |

Contact us |

| BAG-010 | SAMPLE | 940nm (Near infrared side low shift specification) |

Contact us | |

| IR Pass Filter | APF-003 | SAMPLE | 812nm (Low shift specifications) |

Contact us |

From optical thin film design, to dicing and sales

In addition to BAG filters, TAMA Electronics provides a range of services for products such as IR cut filters, AR coating, and bandpass filters - from optical thin film design, to manufacturing and sales.

The entire process from evaporation coating to dicing and inspection is performed on our integrated production lines in cleanrooms, for the highest quality products possible.

Evaporation-coated film: Comparison of absorption type and reflective type IR cut filters

スクロールで図全体をご覧いただけます。

| Type | Reflective type | Absorption type |

|---|---|---|

| Film composition | Filter in which multiple dielectric layers reflect infrared light, letting visible light through | Filter in which an infrared absorption film layer is added to multiple dielectric layers, cutting out infrared light via absorption |

| Features | Incident angle dependence is comparatively high, and there is much infrared half-value shifting | There is very little shifting of the half-value caused by the angle of incidence, compared with reflective type products; these are now used for most IR cut filters found in high resolution camera modules installed in smartphones and other products |

| Key point | Low cost | High performance |

Absorption type (BAG type)

TAMA Electronics absorption type IR cut filters (BAG filters) are optical filters manufactured by coating a reflective type IR cut filter with an infrared absorption layer. This gives them the same or better optical characteristics and strength of conventional BG (Blue Glass) type products.

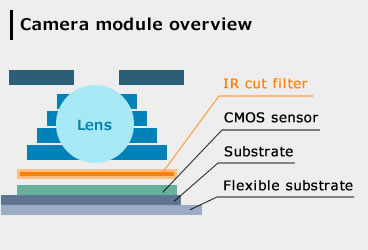

IR cut filters (infrared cut filters)

IR cut filters, generally referred to as "infrared cut filters" or "optical filters," are a component part of the digital camera modules installed in smartphones and other products.

Semiconductor image sensors called CCDs or CMOSs, which serve as key components for these camera modules, are capable of recognizing light up to the infrared spectrum - which is invisible to the human eye. Infrared light must therefore be cut from the resulting image if it is to appear natural to the naked eye.

An IR cut filter is installed in front of the CCD or CMOS to cut extra infrared light from the wavelength band of light, resulting in an image that is closer to how the human eye would see the object.

Antireflection film (AR coating)

AR coating is a form of coating in which low refractive material and high refractive material are alternately layered, causing the interference phenomenon to reduce reflection and improve transmittance. This is useful in increasing optical transmittance, preventing background reflections, and more.

TAMA Electronics is equipped with integrated production lines that handle the entire process, from AR coating design to size cutting.

[Film design -> IR film evaporation coating -> AR film evaporation coating -> Dicing -> Packaging/shipping]