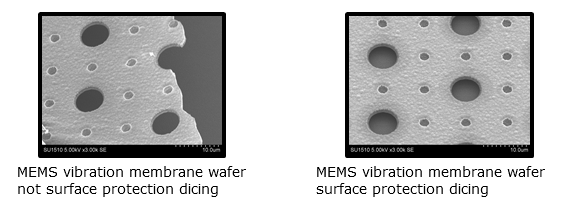

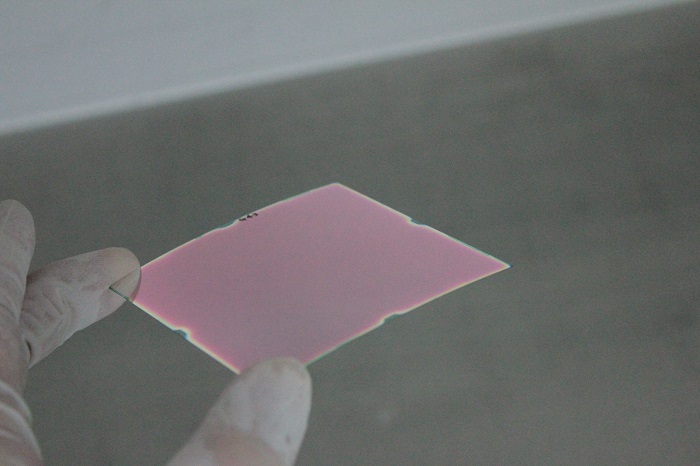

MEMS dicing: Surface protection dicing

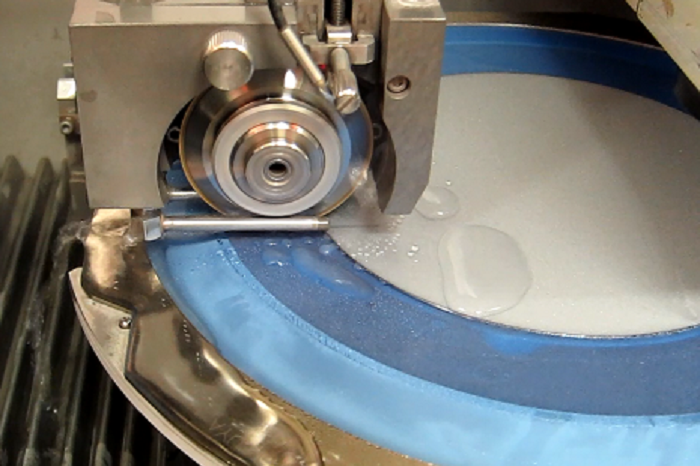

A laser method (stealth dicing) is mainly used when cutting MEMS semiconductor wafers or other substrates that cannot be wet machined, in order to prevent damage and dirt. However, machining using laser dicers (stealth dicers) can be very expensive, and these machines are not suited to machining substrates structured from layers of different materials. TAMA Electronics has developed a machining method that uses a special material to protect surfaces in order to minimize damage to substrate surfaces - even using a conventional dicing saw to cut. If you are thinking of cutting MEMS semiconductor wafers or other substrates that cannot be wet machined, please contact us first!

最終.png)